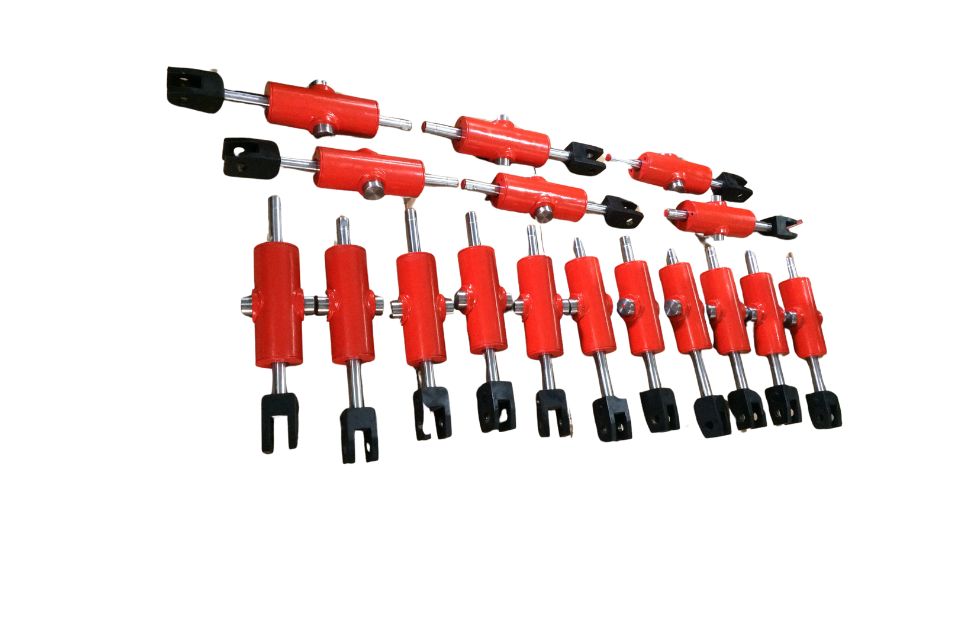

D End Cylinders

"D-end cylinders" typically refer to hydraulic or pneumatic cylinders with D-shaped end caps or mounting configurations. The D-shaped design serves specific purposes in terms of mounting and integration into various systems.

Here are some common features and applications associated with D-end cylinders:

Clevis Mounting:

D-end cylinders often feature a clevis mounting design. The D-shaped end includes clevis pinholes that allow for easy attachment to other components or structures. Clevis mounting provides a secure and versatile connection.

Space-Efficient Design:

The D-shaped end can be more space-efficient than a fully circular end cap. This design is beneficial in applications where space constraints or specific mounting configurations require a more compact shape.

Versatile Attachment:

The D-end design allows for various attachment methods, including clevis pins, bolts, or other fasteners. This versatility makes D-end cylinders adaptable to different mounting scenarios.

Clevis Bracket Compatibility:

Some D-end cylinders may come with integrated clevis brackets or attachments, simplifying the connection to other components or machinery. This feature enhances ease of installation and flexibility in application.

Customization:

D-end cylinders can be customized to meet specific application requirements. This may include variations in stroke length, bore size, and other parameters to suit the needs of the system.

Industrial Applications:

D-end cylinders are commonly used in industrial applications such as manufacturing equipment, material handling systems, agricultural machinery, and more. Their versatility and robust design make them suitable for a range of tasks.

Alignment and Connection:

The D-shaped end aids in aligning and connecting the cylinder with other components. It ensures a secure and stable connection, contributing to the overall reliability of the hydraulic or pneumatic system.

Sturdy Construction:

D-end cylinders are constructed with durability in mind. Materials like steel or alloys are often used to withstand the forces and pressures encountered in hydraulic or pneumatic applications.

Why Choose D End Cylinders?

D-end cylinders for a particular application, it's crucial to consider factors such as load capacity, stroke length, mounting requirements, and the operating environment.