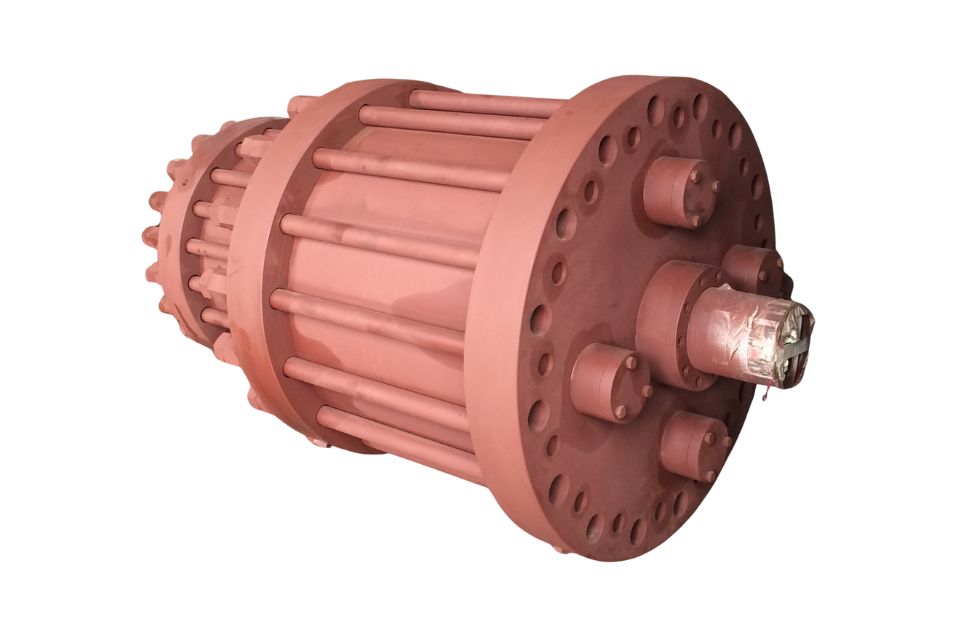

Heavy Duty Parison Control Cylinder

The term "parison control cylinder" is often associated with the plastic extrusion blow molding process, where a parison is a hollow tube of plastic material that is formed and then inflated to create a hollow object. In this context, a heavy-duty parison control cylinder would be a specialized hydraulic cylinder designed for controlling the movement and positioning of the parison during the blow molding process.

Here are key features and considerations for a heavy-duty parison control cylinder:

Heavy-Duty Design:

The cylinder is designed to handle heavy loads and forces associated with the parison control process. This ensures durability and reliability in demanding industrial settings.

Precise Positioning:

The parison control cylinder plays a crucial role in precisely positioning and controlling the movement of the parison. This is essential for creating uniform and high-quality plastic products during the blow molding process.

Hydraulic Actuation:

Hydraulic cylinders are commonly used in parison control systems due to their ability to provide precise and controlled linear motion. The hydraulic system allows for accurate adjustments during the molding process.

High Pressure and Load Capacity:

Heavy-duty parison control cylinders are designed to handle high pressures and loads associated with the extrusion blow molding process. This ensures that the cylinder can exert the necessary force to control the parison effectively.

Fast and Responsive:

Quick response times are crucial for parison control cylinders to enable fast and responsive adjustments during the dynamic blow molding process. This ensures that the parison is shaped accurately and consistently.

Materials and Construction:

The cylinder is typically constructed from high-strength materials, such as steel or specialized alloys, to withstand the forces and pressures encountered in the blow molding environment.

Sealing Technology:

High-quality sealing technology is employed to prevent hydraulic fluid leakage and maintain the integrity of the hydraulic system. Seals must be capable of withstanding the conditions present in the blow molding process.

Integration with Control Systems:

The parison control cylinder is integrated into the overall control system of the blow molding machine. This integration allows for synchronized and coordinated movement during the different stages of the molding process.

Stroke Length and Position Feedback:

The cylinder's stroke length is an important parameter, and position feedback systems, such as sensors or encoders, may be incorporated to ensure accurate positioning of the parison.

Environmental Considerations:

Considerations for the operating environment, such as temperature variations and exposure to plastic materials, may influence the design and choice of materials for the parison control cylinder.

Maintenance:

Regular maintenance is essential to ensure the reliable performance of the parison control cylinder. This includes checking for leaks, inspecting seals, and lubricating moving parts.

Why Choose Heavy-duty parison control cylinders?

Heavy-duty parison control cylinders are critical components in extrusion blow molding machines, contributing to the precision and efficiency of the plastic container manufacturing process. Their robust design and precise control capabilities play a key role in producing high-quality plastic products.